Air compressors are essential across industries like textiles, automotive, shipbuilding, steel, aerospace, and more. They facilitate industrial automation and OEM product development. Custom air compressors are tailored for industries such as Cement, Metal Manufacturing, Chemical, Wastewater Treatment, Pharmaceutical, and Food and Beverages.

Regular maintenance and troubleshooting are required to avoid downtime and reduce losses. A customizable IoT-powered air compressor monitoring system is the ideal solution for efficient operation and risk management.

Highlights of Air Compressor Monitoring System

- Critical parameters monitored in real-time.

- Operational analysis for selected period.

- Remote diagnostics with alerts for unusual activities.

- Operate (On/Off) remotely from anywhere even via mobile app.

- Monitor energy consumption patterns in real-time to boost performance and efficiency.

- Generate custom reports on regular basis to understand the running condition of air compressors.

- Streamline management across multiple sites with a centralized dashboard

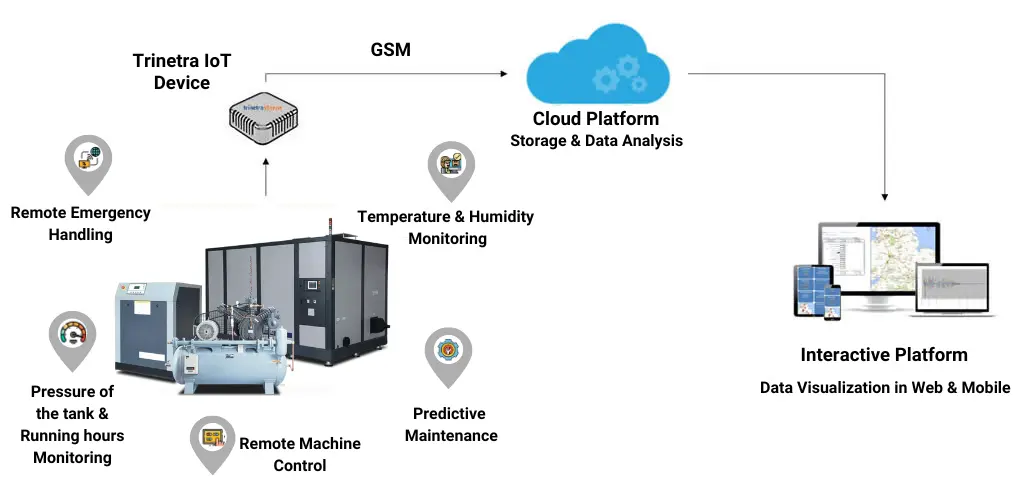

Remote Air Compressor Monitoring System Overview

Engineers traditionally inspect air compressors periodically, leading to maintenance and fault correction costs throughout the equipment’s lifespan. High power consumption and unaddressed faults can cause productivity losses. TSense provides an IoT-based compressor monitoring solution for pneumatic equipment. It helps scale operations, reduces downtime, lowers costs, and improves performance and profitability.

The universal IoT platform, with GPS technology, supports multiple industrial protocols and API integration for efficient data collection. Related equipment like coolers, air dryers, and dehumidifiers can also be integrated.

System Architecture

Monitoring Critical Parameters

We track and monitor various parameters to ensure air compressors are running smoothly without consuming unnecessary power. The parameters include: –

- On/Off Time

- Energy Consumed (kWh)

- Current, Voltage

- Load/Unload Duration

- Power Consumption

- Pressure of the Tank

- Temperature, Humidity

- Coolant Temperature

- Compressor Usage Flowrate

- Motor & Fan Current/Speed

- Running Hours

-

Save up to

30% with improved energy efficiency

(70% of the money you spend on your compressor is on energy) -

Increase your uptime with

3% increase in the availability of your compressor

(8 days increased uptime per compressor per year) -

Operating Efficiency

8% flow efficiency increase on average per compressor per year. (Ensure optimization of your compressor)

-

HSE Risk

75 fewer trips to (Reduce windscreen time, maintenance and repair time)

Key Features

Reports & Analytics

Remote Diagnostic

Automated Alerts & Notifications

Data Security

The Benefits of IOT Integration

Energy Efficiency ImprovedAir compressor monitoring ensures optimal equipment performance, promoting energy efficiency and cost savings.

Detection before issues become criticalOur IoT system monitors various sensors, detecting issues like air pressure drops or leaks early for prompt rectification.

Improving Cost-EffectivenessMonitor equipment for efficiency and longevity, saving costs with predictive maintenance triggered by our system.

To deploy an air compressor monitoring system and improve your productivity & ROI.