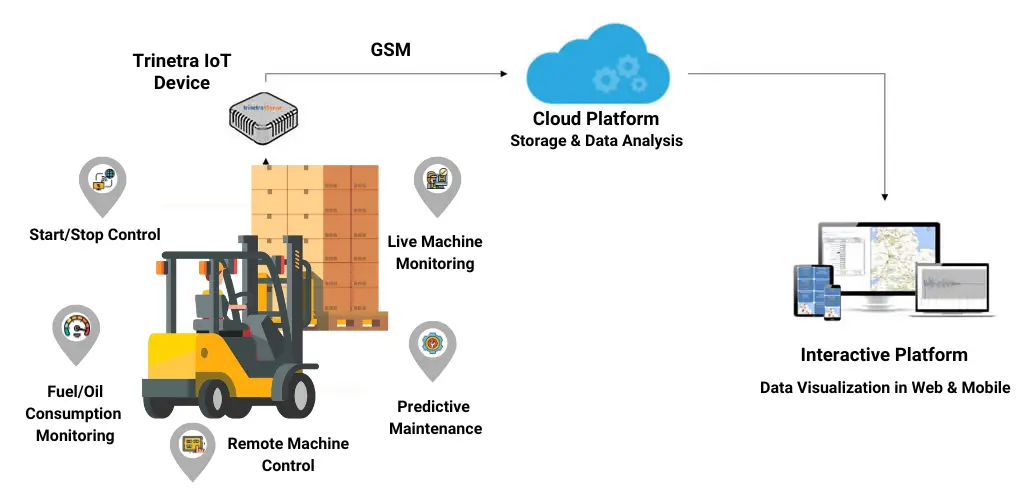

Managing forklift fleets without real-time insights leads to inefficiencies, safety risks and higher costs. Our IoT-based forklift monitoring solution offers comprehensive data, including running hours, engine RPM, tire pressure, and more. Integrated with GPS, geofencing, and remote tracking, it provides actionable alerts to improve operations, enhance safety, and minimize warranty expenses.

Key Challenges Faced

- High Downtime: Unplanned stops due to a lack of preventive measures.

- Safety Concerns: Increased accidents from absent speed limit enforcement.

- Cost Overruns: Rising warranty claims and inefficient fleet management.

- Operational Inefficiency: Challenges in monitoring fuel levels, battery status, and driver behavior.

Solution Offering

- Remote Monitoring: Real-time tracking of forklifts’ location, usage, and performance metrics.

- Alerts and Safety Features: Instant notifications for speed violations, collisions, and critical conditions.

- Preventive Maintenance: Predictive insights reduce downtime and maintenance costs.

- Driver Performance Analysis: Improve safety with driver ID tracking and behavior analytics.

- Start/Stop Control: Prevent unauthorized usage with remote management.

- Web & Mobile App: Access fleet data and alerts anytime, anywhere.

Track Key Performance Indicators (KPIs)

- Running Hours: Maximize fleet utilization.

- Engine RPM & Temperature: Prevent overheating and ensure reliability.

- Tire Pressure & Load Height: Reduce safety risks and extend equipment life.

- Fuel Levels & Battery Status: Optimize energy usage and plan refueling effectively.

- Driver Behavior: Ensure compliance with safety protocols and detect violations.

- Geofencing: Enhance security by preventing unauthorized movements.

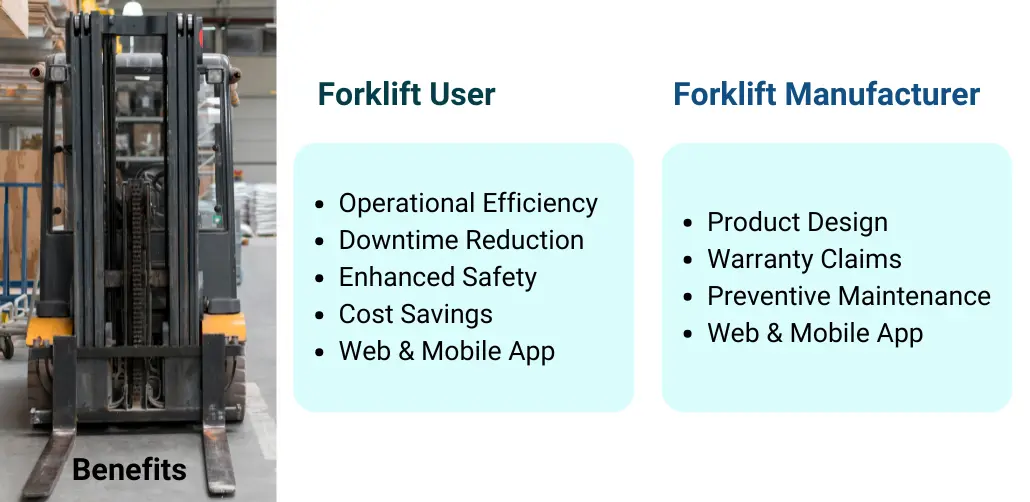

Benefits for Forklift Users

- Enhanced Safety: Alerts for unsafe practices reduce accidents.

- Operational Efficiency: Streamlined workflows with real-time data.

- Cost Savings: Optimized fuel and maintenance reduce expenses.

- Downtime Reduction: Address potential failures proactively.

- Ease of Use: Access data seamlessly via intuitive apps.

Benefits for Forklift Manufacturers

- Preventive Maintenance: Extend equipment lifespan and reduce downtime.

- Improved Product Design: Enhance durability using operational data.

- Reduced Warranty Costs: Lower claims with proactive upkeep.

- Enhanced Customer Satisfaction: Deliver reliable, IoT-enabled solutions.

- Operational Visibility: Monitor real-time forklift usage patterns.

- Data Analytics: Innovate with performance-driven R&D.

Applications

- Logistics: Optimize routes and reduce downtime with real-time tracking and geofencing.

- Warehousing: Streamline inventory and material handling using load height and running hour insights.

- Manufacturing: Prevent disruptions by monitoring fuel levels and engine performance.

- Retail & Distribution: Boost efficiency with real-time analysis of equipment usage and load distribution.

- Construction: Ensure safety by monitoring vibration levels, temperature, and load management.

Revolutionize forklift operations with our IoT-based monitoring solution. Empowered by real-time tracking, predictive maintenance, and smart analytics, you can achieve cost savings, operational efficiency and enhanced safety.

Contact us today to unlock the full potential of your forklift fleet!