An IoT-based Real-time Diesel Generator Monitoring System will assist manufacturing companies, businesses, IT firms, restaurants, hospitals, hotels and apartments in monitoring generators installed at multiple sites, ensuring the proper functioning of backup power.

This system is equally applicable to industrial, commercial and rental generators, providing comprehensive real-time insights and remote management capabilities. It offers benefits such as predictive maintenance, customizable alerts, data analytics, enhancing operational continuity and efficiency across diverse sectors.

We offer a comprehensive remote monitoring solution for all models of Perkins, Kirloskar and Cummins Generators.

Solution Highlights

- Remote Monitoring: Prevent issues with real-time visibility across single or multiple locations

- Maintain generators proactively: Utilize predictive alerts to prevent potential issues and optimize performance

- Maximize fuel efficiency: Cut costs and boost generator performance for optimal results

- Customize performance reports: Tailor tracking of generator health, efficiency and progress

- Simplify informed choices: Detailed performance analytics enable effective data-driven decision-making

- Enhance uptime with diagnostics: Remote Health Diagnostics improve efficiency and increase profits

- Fuel theft alert solution: Integrating fuel level sensors with alarm systems for real-time monitoring & immediate alerts

- Optimize deployment with metrics: Benchmark utilization across sites to enhance customer satisfaction

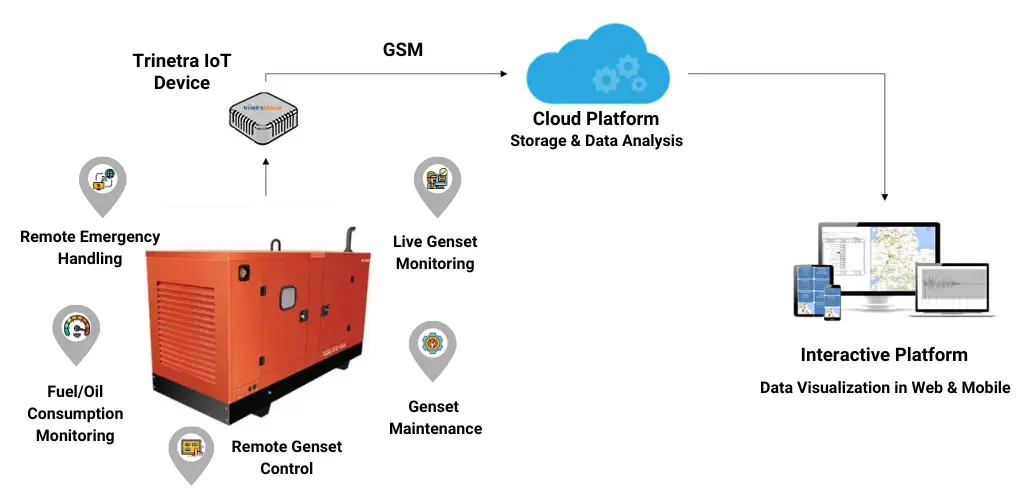

System Architecture

Tools & Technologies

Our expertise spans a wide range of tools and technologies, including:

- Sensor Interconnections (Fuel sensor – LLS, DFM)

- Communication Protocols (e.g., CAN bus, MOD bus RTU, ethernet)

- Cloud Platforms (e.g., AWS, Azure, Google Cloud)

- Edge Computing

- Data Analytics and Visualization dashboard

Remote Diesel Generator Monitoring System Overview

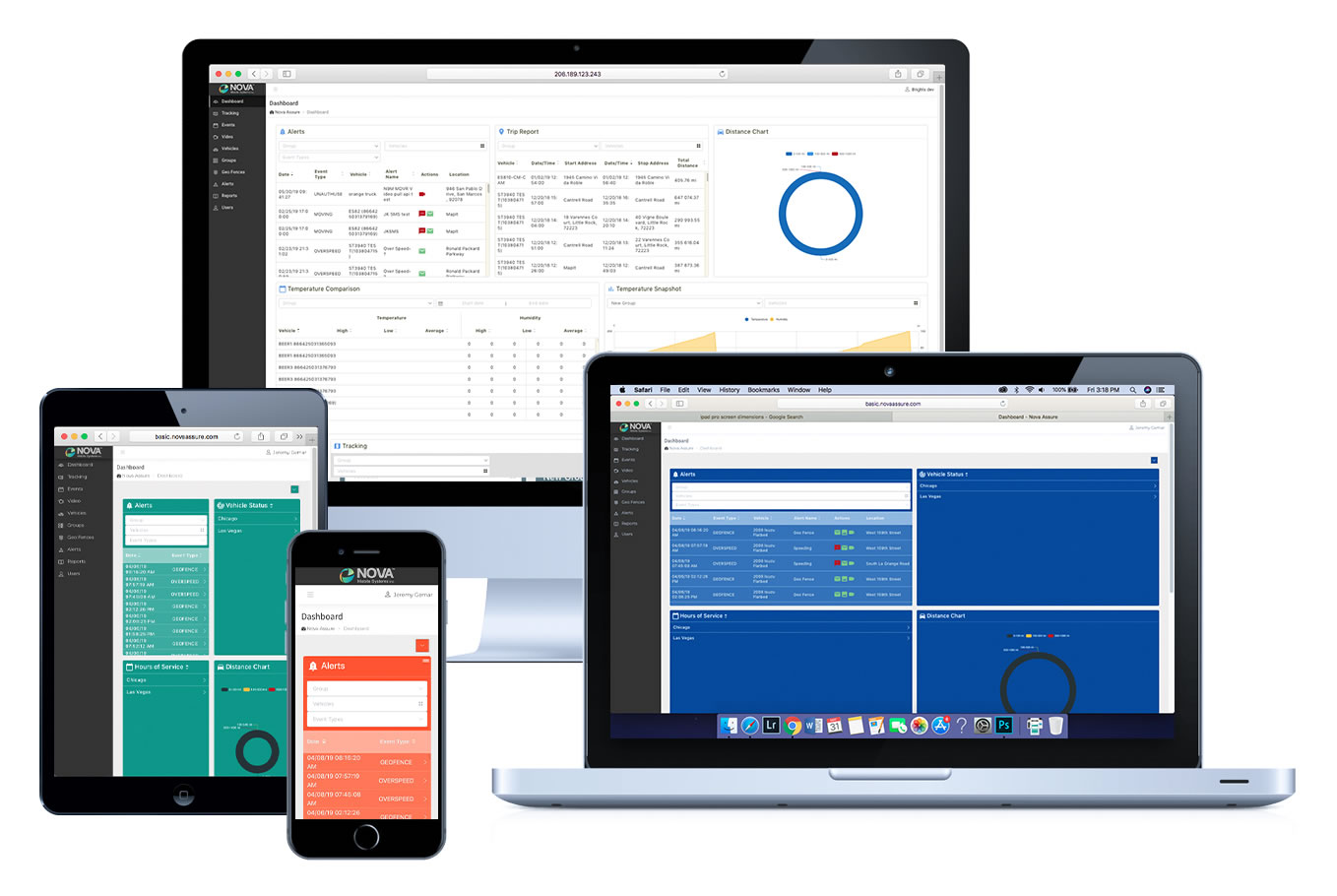

Monitor Multi-sites Generators from Anywhere at Anytime

Calculate Run time, Fuel level, Power generated & react rapidly

Receive Email / SMS Alert Notification for Fuel theft & Faults

Optimize DG utilization and identify cost leakages

Diesel generators are vital for business continuity, and IoT technology makes diesel generators (DG) smart. Organizations willing to optimize the performance of diesel generator sets must obtain remote asset access that provides on-the-go remote access to DGs in various locations via a single dashboard.

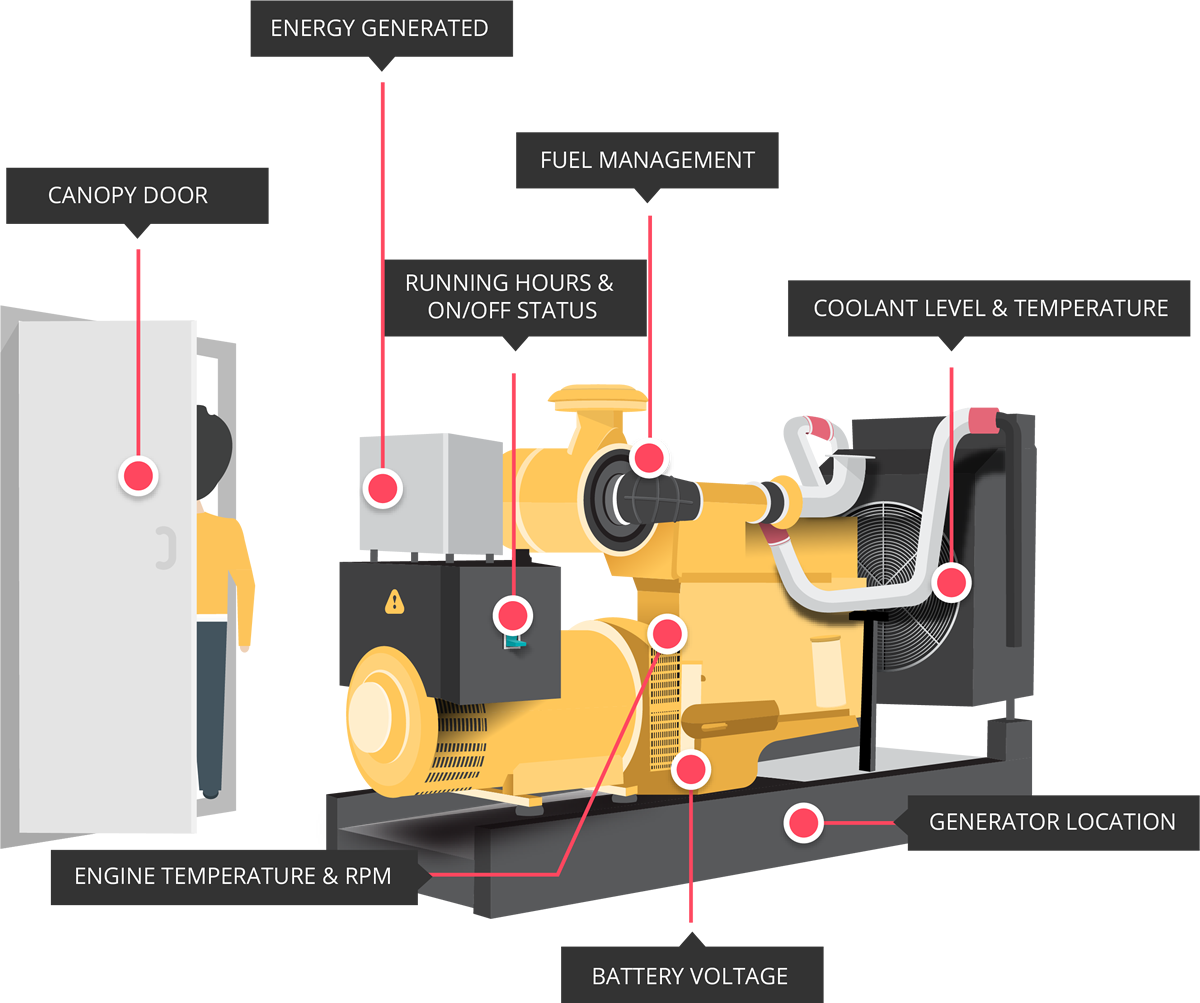

IOT based Diesel Generator Monitoring Solution solves the on-site monitoring and multi-site maintenance requirements of businesses. By deploying remote monitoring of diesel generator system you could detect any anomaly in the generators such as low fuel, theft, leakage, overheating, noise levels, engine temperature, vibration, unforeseen breakdown, etc.

The data captured in the field and processed by IOT platform serves as a valuable repository for diesel generator manufacturing OEM’s, Genset service Engineers and end users.

Diesel Generator Monitoring Parameters

Features

-

Intuitive Dashboard

-

Real-time alerting

-

Fuel monitoring and tracking

-

Remote management (On/Off & Lock/Unlock)

-

Security and surveillance

-

Scheduled Reports

Impact of IOT integration to Diesel Generator Monitoring System

IoT sensors installed in the Diesel Generator makes it smart. End-to-end automation enables businesses to achieve maximum with existing Infrastructure.

IoT integration helps monitoring in near real time from anywhere through the internet, resulting in business gains through efficient management and reduced ownership costs.

Overall Benefits

- Facilitate smooth operations

- Fault & Fuel theft detection

- Predict & prevent Issues

- Optimise DG Power Generation

- Enhance customers experience

- Prevents unauthorized Usage

- Smart Reports on a daily, weekly and monthly basis

Diesel Generator Monitoring Field of Application

Business Owners & Operators of Genset (O&Ms service Person)

Collecting Insight Data for accounting and predictive maintenance

Servicing companies, engaged in DG maintenance and repairs

Maintenance Scheduling & Management of consumables replacement

Diesel Generator Manufacturing for OEM’s

Gathering failure statistics, planning adjustments to genset design

To deploy a smart generator monitoring system and improve your diesel generator’s efficiency.