Digitalization has significantly impacted the cleaning equipment manufacturing industry, leading to improved efficiency and cost reduction. The integration of IoT technology allows manufacturers and suppliers to gain real-time visibility of their machine fleets, enabling effective asset management. Access to data such as machine working time, downtime and geographic locations helps prevent mishaps and optimize operations. IoT integration is seen as a seamless solution for the cleaning sector, driving enhanced efficiencies and meeting industry standards.

Highlights of Industrial Cleaning Machine Monitoring

- IoT-enabled applications allow facilities managers to track equipment whereabouts and monitor cleaning activity across multiple sites.

- A single dashboard provides the ability to monitor multiple machines on a map, with worldwide position detection by setting geo-fences.

- Feasibility to check data ensures appropriate usage of cleaning machines for the estimated length of time.

- Helps companies track machine utilization data and identify patterns that might cause problems.

Remote Cleaning Equipment Monitoring System Overview

The more connected you are, the more efficient you will be. In line with this statement, the Internet of Things provides a solution to connect and manage all sensors and data in one place. By having operational data on your fleet, you can ensure transparency and increase profitability.

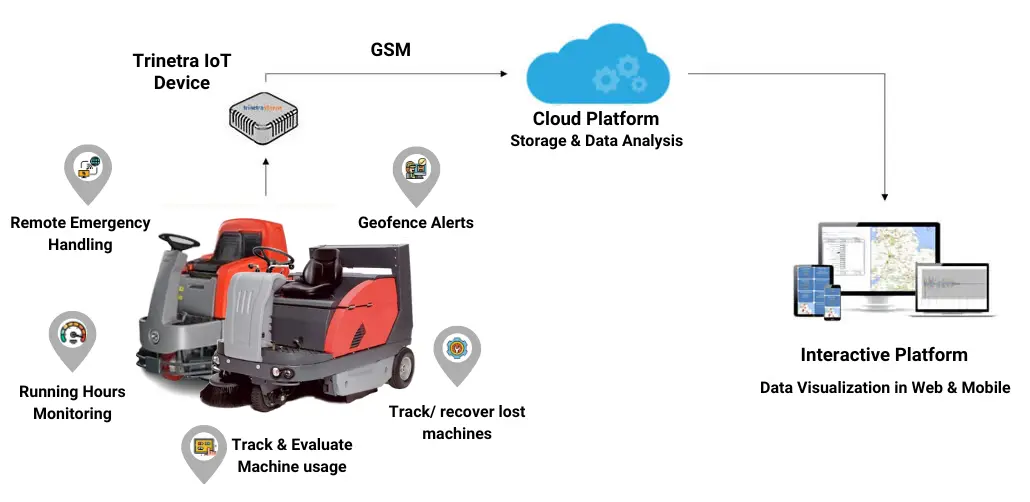

System Architecture

Monitoring Parameters

✔ Set up geo fences to receive real time alerts

✔ Track/ recover lost machines

- Worldwide Position detection

- Set Machine boundaries (geo-fence) and get alerts when a machine leaves the boundaries.

- Easily locate missing machines & Recover stolen machines

✔ Track & Evaluate Machine usage

- Monitoring of adherence to cleaning schedule Helps increase customer satisfaction reduce customer complaints

- Keep track of cleaning hours per day Data supports Showcase proof of work done to the customer

- Evaluating machine utilization trends monthly Increase the quality of resource planning utilization

- Identify Idle or poorly used machines An average underutilization of about 30% reduce cost by 5%

The Benefits of IOT Integration

Centrally manage your fleet of equipment by continuously monitoring the status and position of each machine.

Overcome the risk of losing machinery or equipment with location data and alerts on inappropriate usage.

Adhere to cleaning machine servicing schedules to extend machine life and minimize replacement costs.

24/7 data availability enables optimizing machine deployment, reducing downtime and improves ROI.

Cleaning Machine Monitoring Features

Reports & Analytics

Remote Diagnostic

Automated Alerts & Notifications