As IoT can drive early demand for services and support, it is enabling OEMs (Original Equipment Manufacturers) and ODMs (Original Design Manufacturers) to extend their research and design processes with end-to-end solutions and capabilities. Adopting Industrial Internet of Things (IIoT) allows OEMs to compete effectively with not only third-party service providers but with in-house maintenance services, improving growth and profit margins for the companies involved. Leveraging the IIoT can bring numerous benefits to (OEMs) and (ODMs) in various industries. Here are some of the key benefits:

-

Increased operational efficiency:

IIoT enables OEMs and ODMs in real-time monitoring and data collection from equipment. It allows OEMs and ODMs to optimize production processes, minimize downtime, and improve overall operational efficiency. It helps identify bottlenecks, predict maintenance needs, and streamline their workflows.

-

Enhanced product quality:

IIoT allows for better product quality control through continuous monitoring of production parameters and equipment performance. Manufacturers can detect and address issues promptly, reducing defects and improving product reliability. Data analytics and machine learning algorithms can also be applied to optimize production and enhance quality.

-

Predictive maintenance:

IIoT enables predictive maintenance by collecting data from sensors embedded in machinery and equipment. This data can be analyzed to identify patterns and indicators of potential failures or maintenance needs. By addressing maintenance proactively, OEMs and ODMs can minimize downtime, reduce costs, and extend the lifespan of equipment.

-

Remote monitoring and control:

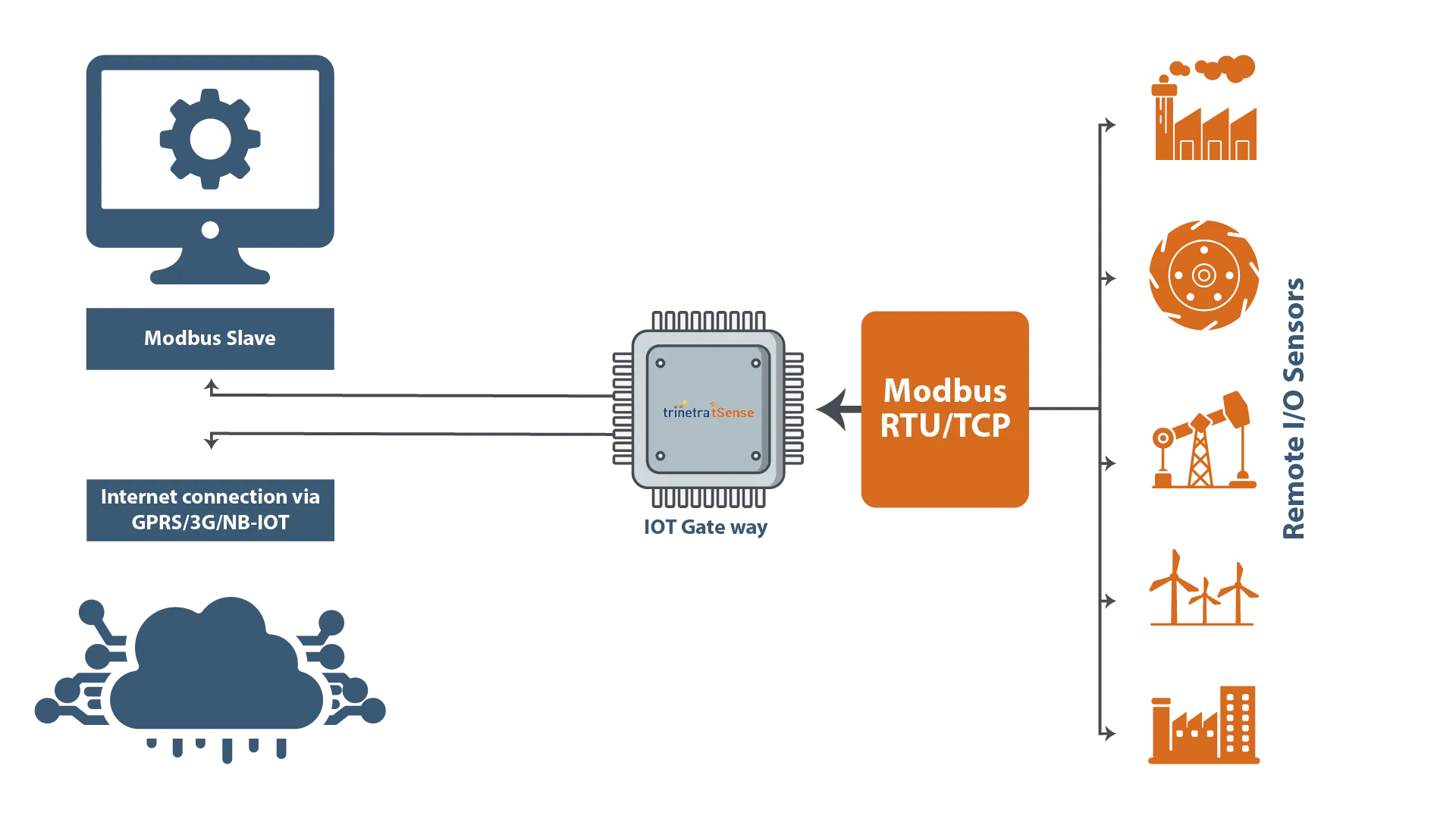

IIoT enables remote monitoring and control of manufacturing processes, allowing OEMs and ODMs to oversee operations from anywhere. This capability facilitates better collaboration, troubleshooting, and decision-making. It also enables experts to provide remote support and guidance to field technicians, reducing the need for on-site visits.

-

Supply chain optimization:

IIoT can provide real-time visibility into the supply chain, enabling OEMs and ODMs to track inventory, monitor logistics, and optimize material flow. This visibility helps minimize delays, streamline procurement, and improve overall supply chain efficiency. It also enables better demand forecasting and inventory management.

-

Cost reduction benefits:

IIoT can contribute to cost reduction in several ways. By optimizing processes, minimizing downtime, and reducing maintenance and repair costs, OEMs and ODMs can achieve significant cost savings. Additionally, improved resource utilization, better inventory management, and streamlined supply chain processes help reduce operational expenses.

-

Data-driven insights:

IIoT generates vast amounts of data that can be analyzed to gain valuable insights. By leveraging advanced analytics and machine learning algorithms, OEMs and ODMs can uncover patterns, identify optimization opportunities, and make data-driven decisions. These insights can lead to continuous improvement, innovation, and competitive advantage.

-

Enhance customer experience:

IIoT can enable OEMs and ODMs to offer value-added services to their customers. For example, connected devices can provide real-time monitoring, remote diagnostics, and predictive maintenance alerts, ensuring uninterrupted operations/uptime for customers. This enhanced customer experience and satisfaction promote long-term relationships.

In general, leveraging IIoT is a potential game changer as it can empower OEMs and ODMs with greater operational visibility, efficiency, and control, leading to improved productivity, reduced costs, and enhanced customer satisfaction. Trinetra T-sense offers secure, scalable IoT software solutions for OEMs. Our custom-made IoT-based solutions earlier delivered show our relevant expertise and experience in IIoT projects. Know more by submitting the enquiry form online, or just mail us a request and we’ll be get back to you.